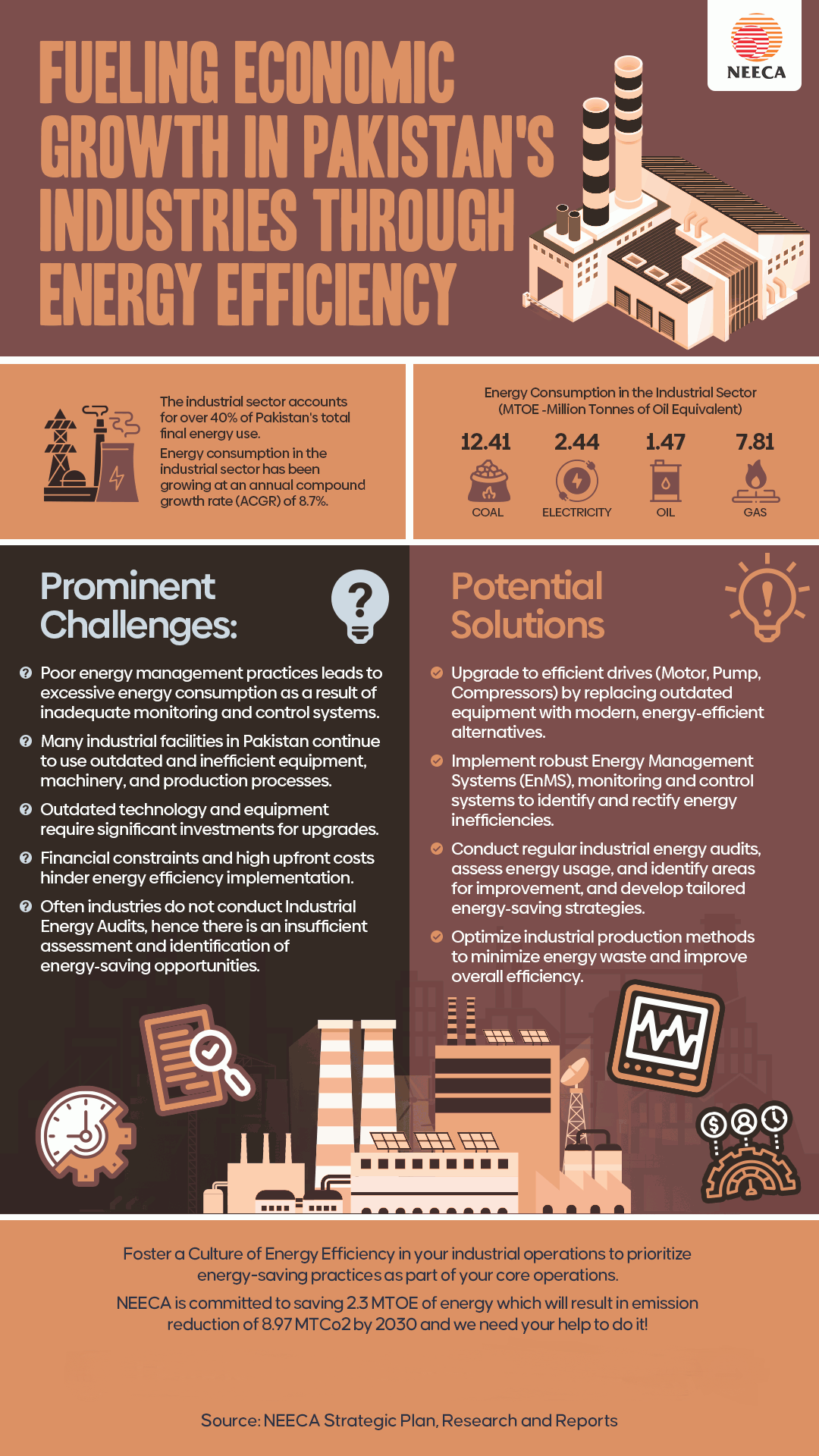

The industrial sector is the largest energy consuming sector, accounting for over 40% of total final energy use in Pakistan. Hence, tremendous energy-saving potential exists within the sector, making exports more competitive. With an intensity of 0.117 kgoe/$GDP(PPP), our industrial sector's energy consumption is significantly higher than that of regional economies. Furthermore, international markets are increasingly demanding products with higher energy efficiency to reduce carbon emissions

NEECA's Initiative: Driving Energy Efficiency in Industries:

NEECA, with its commitment to energy efficiency and conservation, has launched several key interventions in the industrial sector. These measures aim to improve energy efficiency, reduce emissions, and enhance the competitiveness of our industries in the global marketplace.

One of NEECA's significant interventions is the launch of Minimum Energy Performance Standards (MEPS) for large industrial motors leading to substantial electricity savings, cost reductions, peak load reduction, and CO2 emissions reduction. By promoting the use of more efficient motors, we can significantly reduce energy waste and enhance productivity across various industries. Additionally, NEECA is spearheading boiler and furnace retrofitting and replacement programs to improve energy efficiency and ensure all inefficient units.

Moreover, NEECA emphasizes the importance of mandatory energy audits, energy management systems, and the deployment of energy managers in designated industrial consumers. These measures enable businesses to identify energy-saving opportunities, develop actionable plans, and effectively manage their energy consumption, ultimately leading to reduced costs and improved competitiveness.

Q&A session with Feroz Mahmood Baig, Director Industry at NEECA

Impact of NEECA's Initiative:

NEECA's interventions have the potential to drive substantial energy savings and emission reductions in the industrial sector. With an estimated total energy saving potential of 39%, our industries can become more globally competitive. By optimizing energy use in key sectors such as textiles, cement, steel, sugar mills, and the leather industry, we can unlock tremendous energy savings and boost productivity.

Your Role in Achieving Energy Efficiency Goals in Industrial Sector:

As individuals and businesses, we all have a role to play in driving the energy efficiency revolution in the industrial sector. We encourage industrial stakeholders to collaborate with NEECA, embrace energy-efficient practices, and take advantage of the available programs and initiatives. Consider implementing energy management systems, conducting energy audits, and upgrading to more efficient motors, boilers, and furnaces. By collectively adopting energy efficiency measures, we can contribute to a more efficient future, enhance our competitiveness, and position Pakistan as a leader in energy-efficient industries.

Join NEECA in this transformative journey towards a more competitive industrial sector. Let's work together to unlock the immense energy-saving potential within our industries and shape a brighter future for Pakistan.

What is stopping you from adopting energy conservation and efficiency practices in your daily life? #PMsEnergyReforms #NEECA #EfficientEnergy

— NEECA (@NEECA_Pakistan) July 25, 2023

"We are still manufacturing Fans of 120 W and 100 W while Fans with capacity 40 W and even 30 W are also available, and it is a globally adopted technology. We can address the issues of peak loads by adopting energy-efficient technologies."

Khawaja Asif

THE INDUSTRIAL SECTOR IS THE LARGEST CONSUMER:

OVER 40% OF TOTAL FINAL ENERGY USE IN PAKISTAN

Industry is responsible for the largest share of energy use at 37.1 percent. The industrial sector is highly energy intensive with an intensity of 0.117 kgoe/$GDP(PPP) versus 0.08 kgoe/$GDP in Europe5.Internationally, there is an increasing demand of products with higher levels of energy efficiency as a mean to reduce carbon emissions. Pakistan’s traditional export markets are adopting various trade tools i.e. EU’s CBAM/GSP+ etc. to reduce GHG emissions.

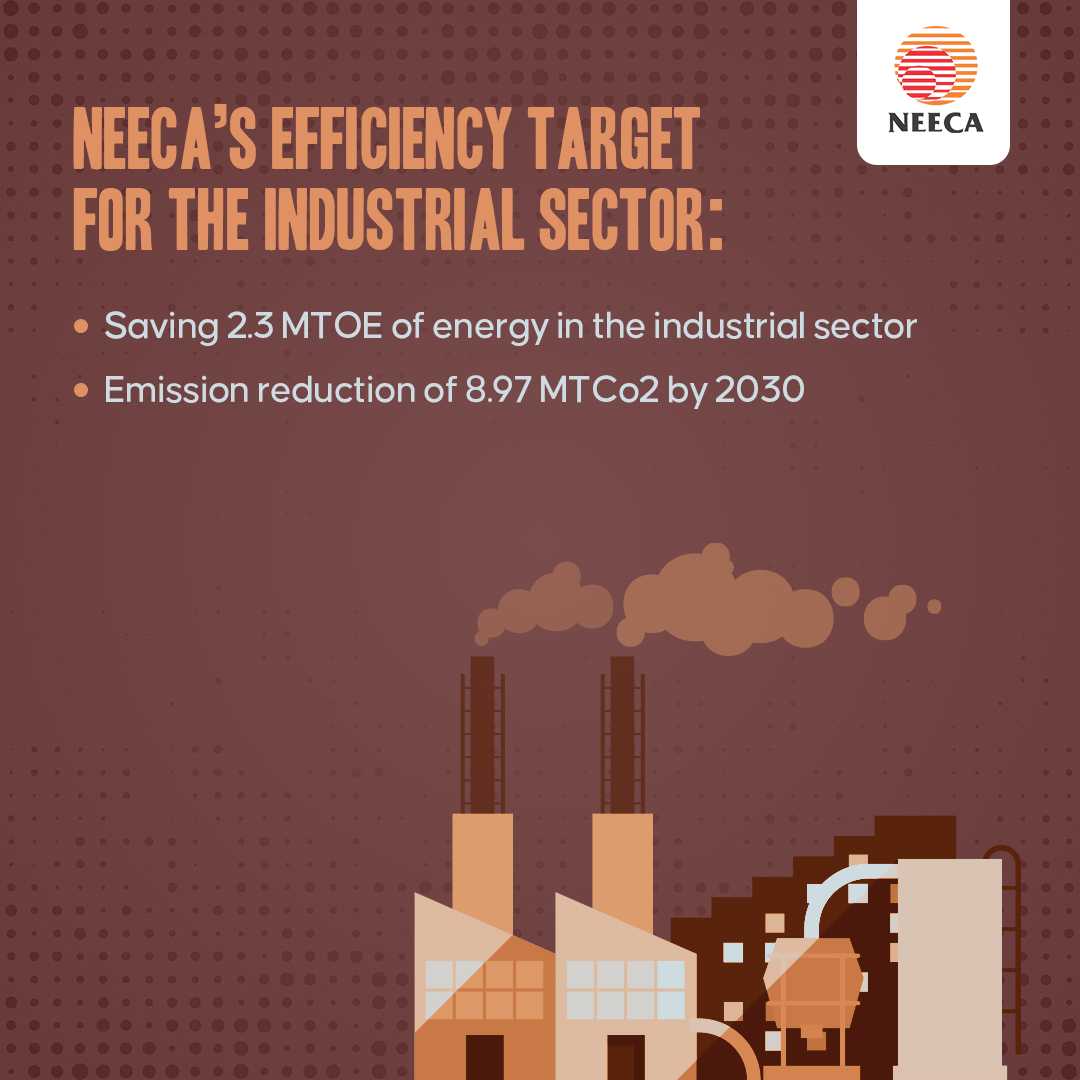

NEECA'S EFFICIENCY TARGET FOR THE INDUSTRIAL SECTOR:

The target of saving 2.3 MTOE of energy which will result in emission reduction of 8.97 MTCo2 by 2030. The government is implementing various energy efficiency measures in the industrial sector, including a ban on motors below IE2 standards by 2027. Additionally, there will be efforts to retrofit or replace inefficient industrial boilers and furnaces by 2026 and mandatory energy audits with five-year energy-saving plans for designated industrial consumers by the same year. To further enhance energy management, energy managers and Energy Management Systems (EnMS) will be deployed across the industrial sector by 2026.

NEECA INITIATIVES:INTRODUCING COUNTRY'S FIRST ENERGY EFFICIENCY REGULATIONS FOR INDUSTRIAL MOTORS

Motors play a crucial role in the functioning of many industrial processes. They are used to power a wide variety of machines and equipment, ranging from conveyor systems to pumps, fans, compressors, and more. Majority of the motors manufactured and used in the industry are of very poor efficiency (even below IE1) which places enormous stress on the economy, both in terms of direct costs to the motor user, and the indirect costs to the generation and distribution companies to meet the peak demand attributable to motors. To implement the minimum energy performance standards (MEPS) for Motors. This action will save approx. 0.75 MToE annual energy from electricity. The financial impact of this electricity savings is estimated as 155 Million USD per year. The saving shall reduce approx. 4.4 Million tonnes of CO2 emissions per annum.

NEECA'S INITIATIVE: INDUSTRIAL BOILER TUNE-UPS, RETROFITTING, AND REPLACEMENT

The replacement of inefficient boilers and the implementation of tune-up programs in industrial settings can result in substantial energy savings. Inefficient boilers often consume excessive amounts of fuel to generate the necessary heat, leading to higher energy costs and increased greenhouse gas emissions. By replacing these outdated and inefficient systems with more modern and energy-efficient models, industries can reduce their energy consumption and operating costs significantly. Additionally, tune-up programs involve fine-tuning and optimizing the performance of existing boilers, ensuring they operate at peak efficiency. This involves adjustments to combustion processes, insulation improvements, and other measures that help boilers use less energy while maintaining their effectiveness.

NEECA'S INITIATIVE: INTRODUCTION OF ZIG-ZAG TECHNOLOGY IN BRICK

Zig-zag technology is a game-changer in the realm of brick manufacturing. This innovation can cut fuel consumption by as much as 30% while simultaneously minimizing emissions. It ushers in a cleaner and more sustainable approach to brick production. By utilizing this technology, the industry not only reduces its environmental footprint but also enhances cost-efficiency, making it a pivotal step towards greener and more economically viable brick manufacturing practices.

The Industrial sector acounts for over 40% of Pakistan's the total final energy use

Energy consumption in the Industrial Sector has been growing at an

annual compound growth rate (ACGR) of 8.7%.

Foster a culture of energy-efficieny in your industrial operation to prioritize

energy-saving practices as part in your core operations.